输入关键词开始搜索

输入关键词开始搜索

Engineered for excellence with cutting-edge technology and precision manufacturing

Achieve Consistent Plating Quality Across the Entire Workpiece. Ultra-low ripple DC output ensures stable current delivery during electroplating, effectively minimizing thickness deviation and surface defects. This is especially critical for fine-line PCB copper plating and precision surface finishing processes. Why it matters to you: 1.Improved plating. 2.uniformity. 3.Higher product yield. 4.Reduced rework and scrap rate.

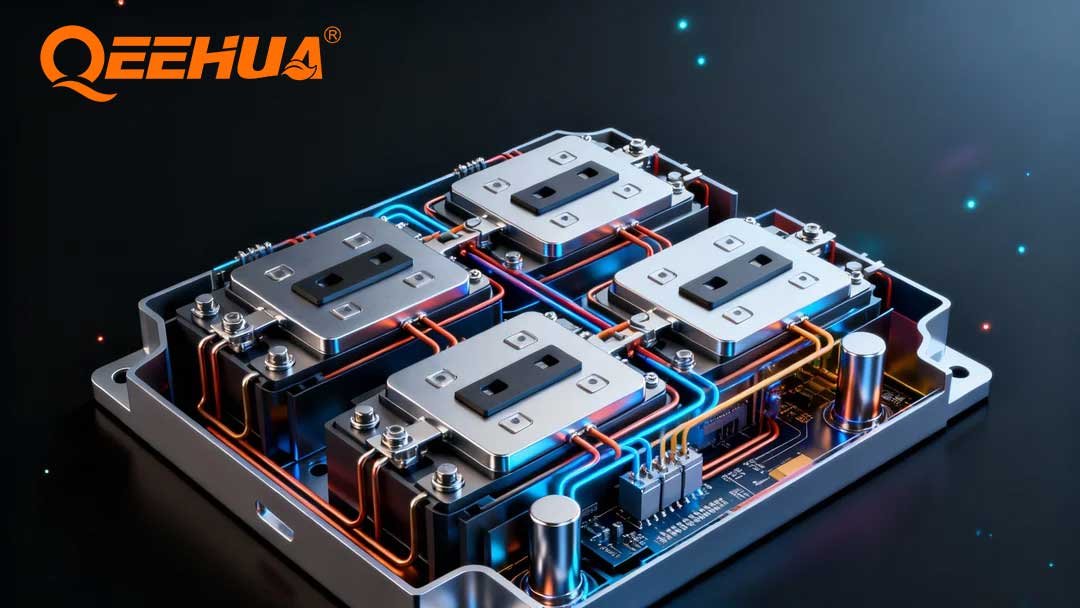

Reliable Power Delivery for High-Load Electroplating Operations. The four-channel IGBT modular parallel architecture enables stable high-current output while distributing electrical stress evenly across modules. This design improves system reliability and allows easy maintenance or future capacity expansion. Why it matters to you: 1.Stable operation under continuous high-load conditions. 2.Reduced downtime risk. 3.Easier maintenance and scalability.

Lower Energy Consumption with Higher Electrical Efficiency. Designed with a high power factor, the rectifier significantly reduces reactive power loss and improves overall energy utilization. This helps electroplating plants lower electricity costs while meeting modern energy efficiency and environmental standards. Why it matters to you: 1.Reduced operating costs. 2.Improved energy efficiency. 3.Compliance with environmental and electrical regulations.

Flexible Control Architecture for Different Process Requirements. The scalable main control board supports precise adjustment of voltage, current, and operating parameters. It allows seamless integration with different electroplating processes and enables future upgrades without replacing the entire system. Why it matters to you: 1.Easy parameter tuning for different plating processes. 2.Future-proof system design. 3.Better process repeatability and consistency.

Comprehensive Safety Protection for Long-Term Reliability. Multiple built-in protection mechanisms safeguard the system against over-voltage, over-current, overheating, and short circuits. This ensures safe, stable operation even under harsh industrial environments. Why it matters to you: 1.Enhanced equipment safety. 2.Reduced risk of unexpected shutdowns. 3.Longer service life of power components

Real-Time Monitoring for Improved Process Control. The integrated networked control system enables remote monitoring and parameter adjustment through industrial communication interfaces. Operators can quickly respond to process changes and maintain consistent plating quality. Why it matters to you: 1.Real-time process visibility. 2.Faster troubleshooting and response. 3.Improved production efficiency and consistency.

Precision-engineered parameters for optimal performance and reliability

| Parameter | Value | Unit | Note |

|---|---|---|---|

|

Input Voltage

|

3-Phase 380VAC±10% | - | - |

|

Voltage Regulation Accuracy

|

1.5% or Less | - | - |

|

Power Factor

|

PF≥0.9 (Under Rated Working Conditions) | - | - |

|

Regulation Mode

|

RS485 Communication, Remote Controller | - | - |

|

Protection Mode

|

Over Temperature, Over Current, Lack Of Phase | - | - |

|

Conversion Efficiency

|

88% (Id≥50%) | - | - |

|

Place of Use

|

Indoor, No Direct Sunlight | - | - |

|

Altitude

|

Below 2500 m | - | - |

|

Output Voltage

|

0−12V, 0−24V Adjustable Linear | - | - |

|

Output Current

|

0−2000A Adjustable Linear | - | - |

|

Temperature Environment

|

−20℃ −45℃ | - | - |

|

Control Mode

|

CC & CV | - | - |

|

Current Ripple

|

3% or Less | - | - |

Get personalized recommendations based on your specific electroplating requirements. Our technical team will help you find the perfect solution.

Precise measurements for optimal installation planning

| Model | Width (mm) | Depth (mm) | Height (mm) | Notes |

|---|---|---|---|---|

| QE-SCHS-A | 468 | 476 | 676 |

QEEHUA stays at the forefront of global technological advancement, committed to providing customers with high-quality power supplies and professional integrated services.

With advanced design and extensive rectifier manufacturing experience, we deliver optimal power solutions and the most stable, efficient power supplies for our users.

Next-generation IGBT modules with advanced circuit design achieve >95% conversion efficiency and only 0.1-0.2V voltage drop

Voltage and current regulation accuracy both exceed <1%, ensuring consistent current density during electroplating

Supports RS485/232, Modbus communication interfaces for remote control and real-time monitoring

Water-cooled and air-cooled series optimized for different power requirements with compact structure and high power density

Industry-leading specifications for superior performance

Complete documentation and support materials

Need help selecting the right electroplating power supply? Our technical experts are ready to analyze your specific requirements and provide customized solutions. Get professional guidance from our engineering team today.

Tell us about your requirements and our technical team will provide customized solutions

Contact us for custom solutions and technical support from our experienced engineering team. We understand your industry needs and provide worldwide support.